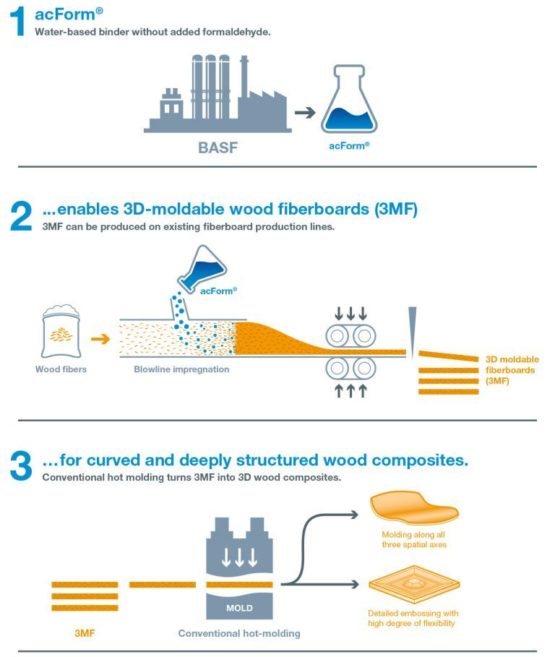

BASF’s acForm enables the production of a new wood-based material for the furniture industry. Specifically, it enables the production of a thermoplastic composite, which is storage-stable and suitable for production on existing MDF production lines.

In contrast to standard thermoset boards, this new wood-based material enables a post-moldability and surface structuring of the MDF panel. This can be achieved in short cycle times by using standard furniture molders’ equipment. The increased moldability of the composite enables new design options. The 3D moldable fiberboards (3MF) can be processed into traditionally molded parts such as seat shells, seat backings, and other curved or deeply structured components. As formaldehyde is not added to the binder system, the working environment is further improved.

BASF offers the possibility of producing acForm based on the biomass balance approach, using 100 % bio-based raw material.